Classification application

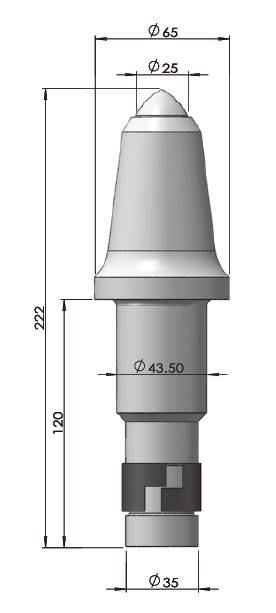

The conical tooth head has strong impact resistance and is suit�able for hard rock or semi-coal rock working conditions.

Low cutting resistance and used for coal seam mining.

Scope of application

Coal mining: Suitable for coal mining machines, boring machines and other equipment, covering coal seams, hard rocks and semi-coal rock formations.

Tunnel engineering: such as shield machines and rotary cutter picks (such as BZ47 series), used for tunnel boring and foundation construction.

Product performance

Impact resistance: Special tooth head design (such as tapered, curved) distributes stress, reduces the risk of broken shank, and adapts to Complex rock conditions.

Process verification: Through hot mounting process and alloy composition optimization (such as increasing Co content), the comprehensive performance reaches the international level, and the domestic replacement cost is reduced by 30% to 50%.