Classification application

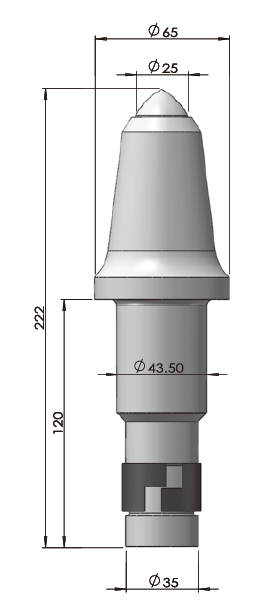

By shape: knife type (low cutting resistance), pick type (suitable for hard rock).

By material: ordinary type, wear-resistant type, sandstone special type (with alloy strips).

Scope of application

In practical applications, suitable rotary digging teeth need to be selected according to the geological characteristics of the con�struction site to ensure construction efficiency and safety.

Product performance

Wear resistance: Cemented carbide tips can still maintain high hardness at high temperatures of 600~800 ° C, but insufficient red hardness may lead to softening and accelerated wear.

Impact resistance: Special geometric tooth head designs (such as tapered, curved) reduce cutting resistance and reduce the risk of broken shank.